High demands - our every day

Quality

The ambition is to follow the market and our customers' requirements in the quality area and we have therefore chosen to certify ourselves against ISO 3834-2. In addition to ISO 3834-2 an internal work is currently underway updating ISO 9001 to the latest version and the goal is certification in 2023.

ASME-BPE is used in our daily work together with standards that handle surface treatments, pressure vessels as well as most standards in electrical and automation.

ISO 9001 & ISO 3834-2 (certificate ISO 3834-2)

Most people know that ISO 9001 is a cross-functional quality management system, but as a welding company it is ISO 3834 that handles the welding-related questions, -2 means that we are certified against the highest requirements and we did so already in 2007. The certification according to ISO 3834-2 means that we have technically documented competence but also that we ensure that we have the correct equipment to enable the work and lay the foundation for the right quality.

Knowledge of customers' processes is a prerequisite for being a supplier to the most demanding industries. We are happy to work with our customers at an early stage to provide input from a manufacturer's perspective. We have several examples of how we, together with customers, have developed new solutions to streamline production processes and at the same time ensure good quality

To prevent the stainless steel from being contaminated, we do not work in black steel, both for our own safety and so that you shall be completely sure that your product do not risk being contaminated.

Pressurization (ackrediteringsbevis ISO/IEC 17020 (C))

Nordholms is accredited by Swedac for pressurization with gas according to ISO / IEC 17020. As a control body according to type C, this means that we can perform checks both on installations performed by ourselves or by another manufacturer / installer.

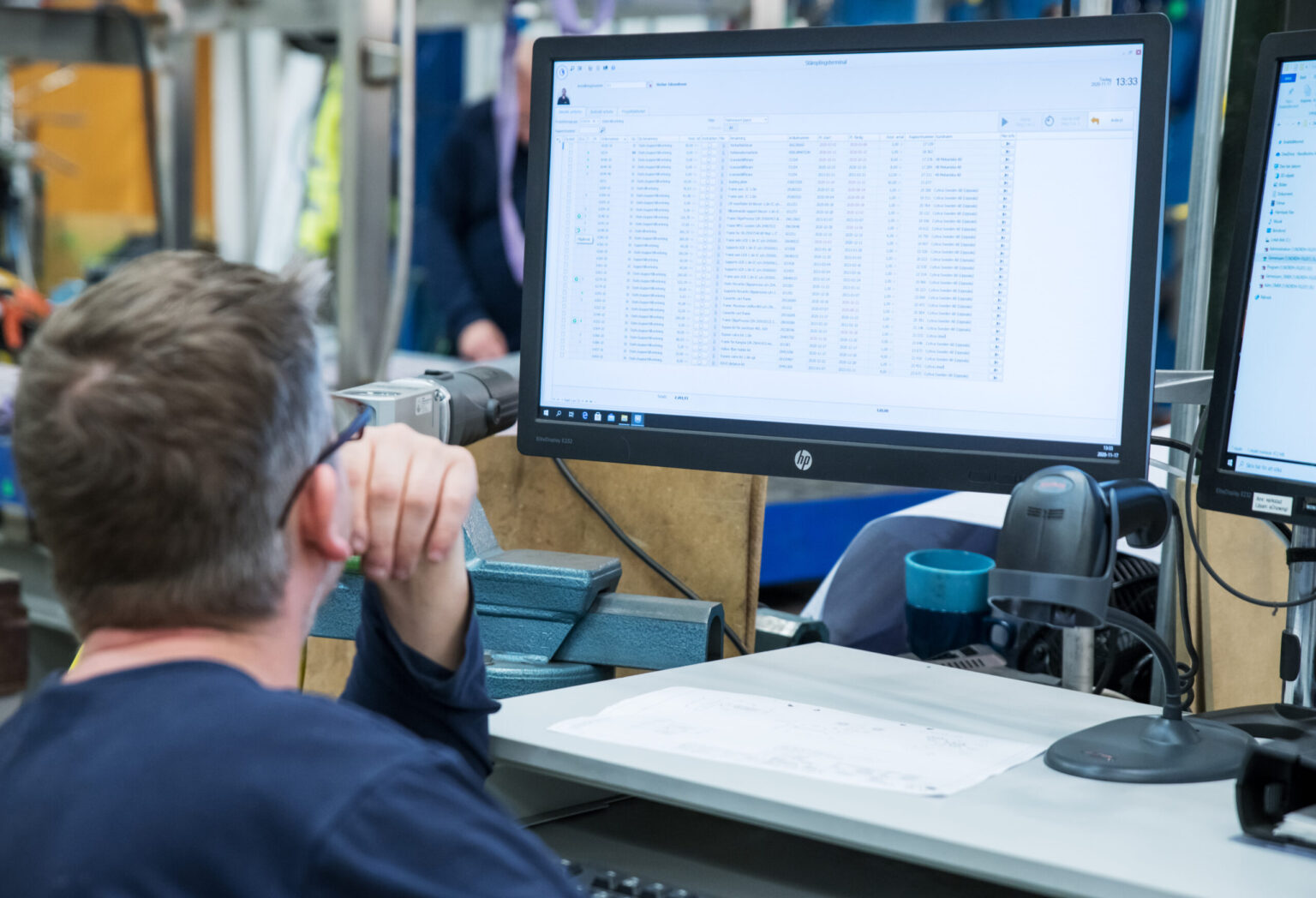

Traceability & identity

The work of maintaining traceability and identity begins already in our goods reception, materials and documentation is checked before it is stored and the items are handled with traceability in our business system, from receipt to delivery. When material is shared, the batch number is transferred so that the traceability of the material is maintained.

All work is documented and several documents are generated in our various production steps which can be delivered together with the goods to the customer.

Quality controls

In the different production steps, several different controls are performed such as:

- Ra-meassuring

- Visual control

- Geometry measurements

- Fiber optic control

- Pressurization

- Leak testing

- Penetrant test

If required 3rd party control in a project, we collaborate with several accredited control companies.

Machines and equipments

Achieving good quality and efficiency requires a combination of knowledge, experience and good tools, which is why in recent years large investments in machines and equipment at both OMEK and Nordholms has been done.